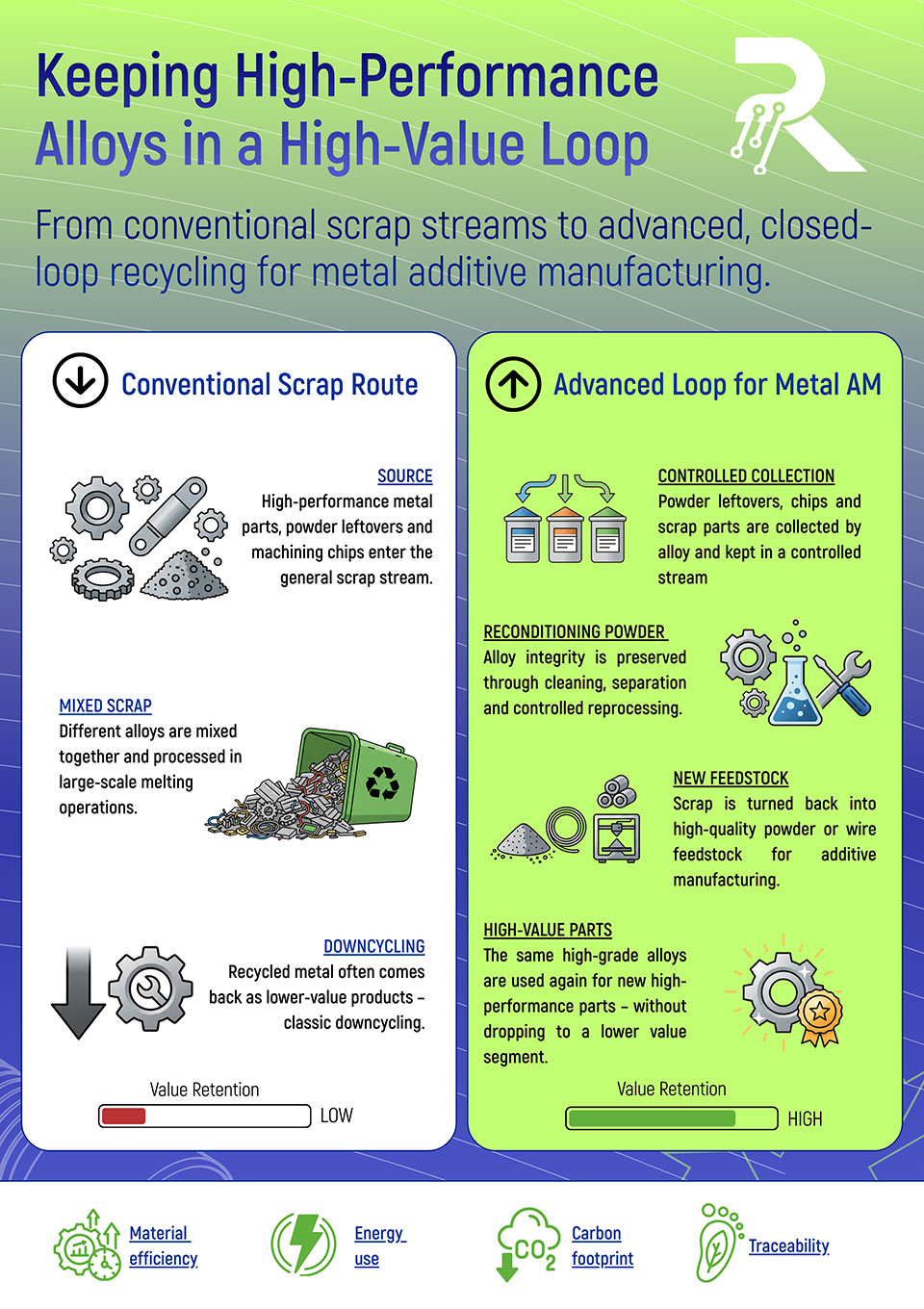

In metal additive manufacturing (AM) processes, powder leftovers, machining chips, and scrap parts often end up in the general scrap stream and are melted together with different alloys. This approach typically results in the recovered metal being turned into lower-value products (downcycling), causing the material’s true potential to be lost.

An advanced closed-loop approach aims to reduce this loss. Materials are separated by alloy, collected in a controlled stream, and their quality is preserved through cleaning, separation, and controlled reprocessing. In this way, scrap can be converted back into high-quality powder or wire feedstock and reused in the same class of high-performance parts.